Permit for Production of Fuel Cells

During the last years, CFCL developed in its research and production units in Australia a new technology for the manufacturing of high performance fuel cells.

The project „High Voltage Ceramic Fuel Production Unit" (HVCFPU) contains as a first step the implementation of a new production facility for fuel cells in Heinsberg.

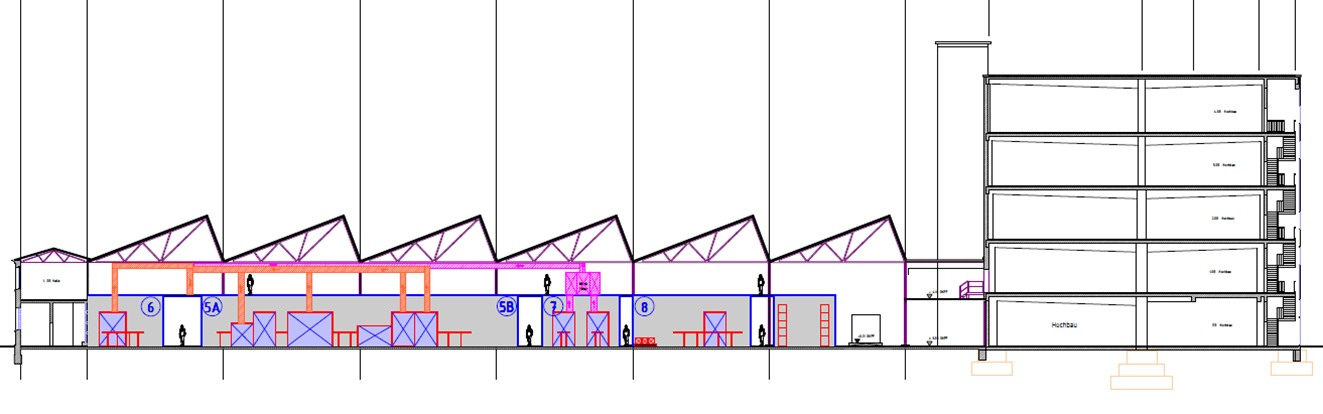

The equipment for a production of 50,000 “Hot-Modules” per year will be installed in an existing industrial building.The process contains the following parts:

raw material; receipt of goods and storage, preparation of the ceramic sludge and of the coating material, casting, laminating and pre-cutting of the multi-layered fuel cell plates, high temperature baking of the laminated plates, A&B screen-print und drying of the ceramic plates, intermediate baking, laser cutting of the ceramic plate to final measurements, assembly of the layer sets and ceramic plates in metal frames, baking of the layer sets, baking of the blocks, mounting of the block groups with the BOP and testing, packaging and logistics, equipment for cleaning of waste gases.

Principal project data

Production of high performance fuel cells.

- 50.000 "Hot-Modules" a year

- euipment installation

Scope IPS

Project Preparation

-

Creation of the documents fort the permitting procedure according to BImSchG

-

Discussion with the authorities

-

Follow up of the permit process to the final permit grant

IPS operational unit(s)

- IPS Germany GmbH